Before answer this question you need to find out the difference (Advantages & Disadvantages) between grauver printing and digital printing.

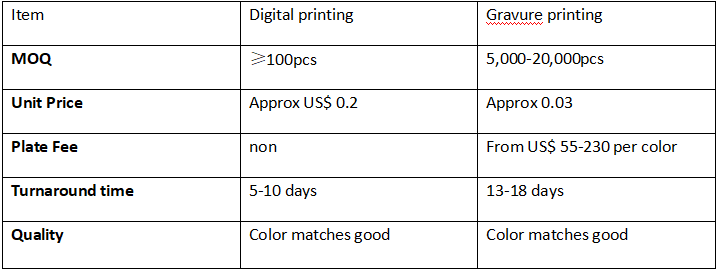

Printing technology is roughly divided into: traditional printing and Non-plate printing (non-contact): traditional printing mainly includes Toppan printing, gravure printing, lithography, screen printing, etc., and non plate printing is divided into: digital printing, inkjet printing , ion spectroscopy, magnetic imaging, thermal imaging. After practical tests, gravure printing and digital printing have become the leader and dominant of printing technology. There is an indistinguishable trend. Here is a list chart that compare from quality, price, turnaround time, MOQ, We takes the pouches 15*20mm 120mic for example

Let's assume the customer wants 10,000pcs bags with 4 colors printed, then digital printing need cost US$ 2000, Gravure printing need cost US$ 620. So the digital

Let’s assume the customers need 1000pcs. Then digital printing cost is US$ 200. But for the gravure printing, only the plate cost will be around US$ 320.

If the order requires a large amount, the cost of digital printing is significantly higher than that of traditional gravure printing. To sum up, digital printing is suitable for high-value-added products with rich colors, multi-series, small batch production or low-volume proofing. Through a small number of proofing product market test marketing research, the packaging with good recognition is selected and then printed by traditional printing methods, which greatly reduces the risk of enterprise product development and reduces operating costs for the enterprise.

Gravure printing Advantages: no color deviation, high color saturation fidelity, and can restore various colors of the design draft in the largest Chengdu. The price can be about 10 times lower than digital printing.

Gravure printing Disadvantages: During printing, the substrate can only be rolled from the beginning to the end, so the process is long, and the MOQ requires at least the amount calculated by one substrate; due to the need for plate making, all spot colors need the captain to use the ink according to the plate. and diluent. Simply put, there is a minimum order quantity requirement.

I am JTD Pack, welcome everyone to communicate and progress together!